Reliable electrical systems are essential for business operations as disruptions can cause major setbacks. Keeping systems secure, efficient, and compliant requires a strategic approach to maintenance and safety. Adopting best practices for electrical integrity helps ensure smooth operations and long-term reliability.

Importance of Regular Inspections and Maintenance

Regular inspections and preventive maintenance are critical components of effective electrical integrity management. Neglecting these aspects can lead to unexpected failures, resulting in costly downtimes and potential safety hazards. Inspections are vital for spotting potential issues, such as wear and tear or corrosion in essential components, before they escalate into major problems.

For instance, scheduling routine electrical inspections in a manufacturing environment can prevent circuit breakers or wiring systems issues that could jeopardise continuous production. By establishing a structured maintenance schedule, businesses ensure all electrical components operate at peak efficiency, thereby minimising the risk of unexpected outages. Incorporating third-party experts equipped with specialised tools for regular assessments can further bolster a proactive maintenance strategy.

Moreover, consistent maintenance cultivates a workplace culture of safety and reliability. Employees become more aware of the importance of electrical safety protocols, leading to fewer accidents and enhanced morale.

Investing in regular inspections protects equipment and secures the well-being of staff, ultimately contributing to a more productive and efficient work environment. Regularly updating and documenting inspection findings can also support compliance with industry regulations, fostering accountability and continuous improvement.

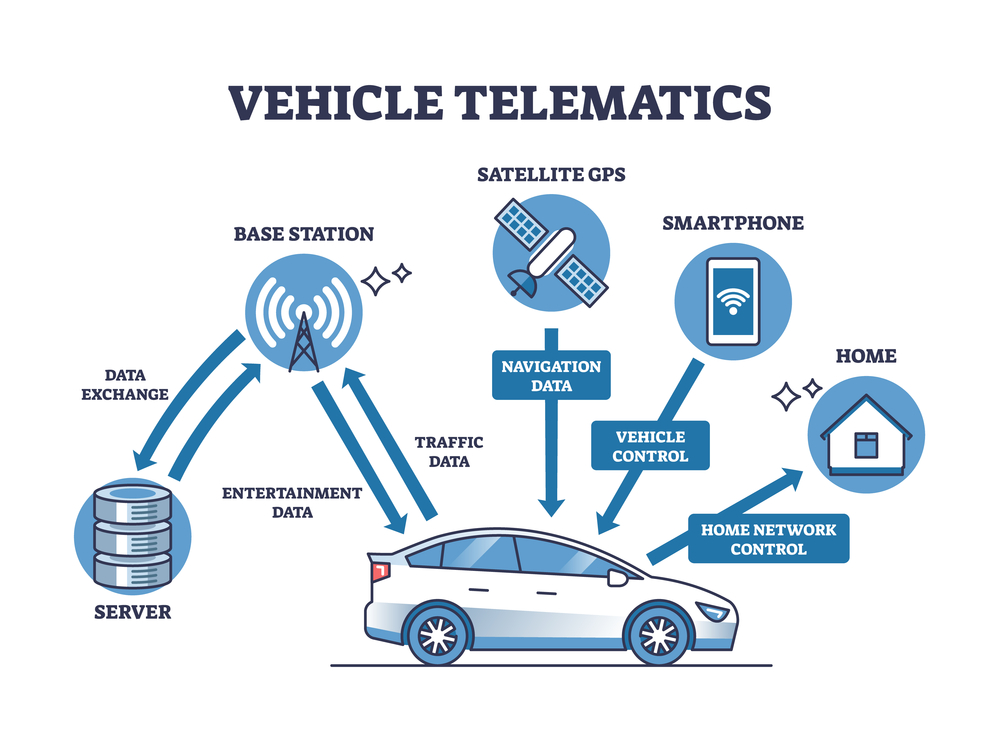

Leveraging Advanced Monitoring Technologies

The rise of advanced monitoring technologies has revolutionised the management of electrical systems in businesses. Real-time data and analytics provide invaluable insights into system performance, aiding informed decision-making. Technologies such as thermal imaging, vibration analysis, and smart sensors allow for continuous monitoring of electrical integrity, similar to the insights garnered from Network Rail CP7 insights.

These technologies offer modern enterprises enhanced reliability and reduced risk. For example, a data centre utilising smart sensors to monitor electrical loads can quickly identify and address anomalies before they interfere with operations. Moreover, these technologies provide immediate alerts and trend analysis, assisting in future planning for necessary upgrades or modifications to electrical systems. Integrating these state-of-the-art technologies is beneficial and critical for businesses striving to maintain a competitive edge.

In addition to enhancing operational efficiency, advanced monitoring technologies facilitate predictive maintenance strategies, allowing businesses to anticipate and address potential issues before they translate into costly disruptions. This forward-thinking approach safeguards assets and optimises resource allocation, resulting in significant cost savings.

Training and Skill Development for Workforce

The workforce’s expertise in electrical systems is crucial to maintaining integrity and safety. Investing in comprehensive training and development programmes empowers employees with the skills and knowledge to manage complex electrical systems effectively.

Training should cover everything from fundamental electrical safety to advanced troubleshooting techniques. In a transportation company, for example, equipping the maintenance crew with training in the latest diagnostic tools can expedite issue resolutions, thereby reducing service disruptions. Continuous learning opportunities create a culture of safety and diligence, prompting employees to stay updated on industry advancements and best practices.

Prioritising workforce training and skill development enhances operational efficiency and improves overall safety. This benefits the employees and reinforces the business’s commitment to maintaining a high standard of electrical integrity.

Furthermore, recognising and rewarding employees for their commitment to ongoing education boosts motivation and fosters a sense of ownership in their roles. As a result, skilled workers are more likely to implement best practices, further ensuring the reliability and safety of electrical systems. Regularly scheduled refresher courses help maintain high proficiency levels among employees, ensuring they remain equipped to handle challenges effectively.

Implementing Robust Standards and Compliance Measures

Adhering to established standards and compliance measures provides businesses with a framework to maintain high levels of electrical integrity. Compliance with industry-specific regulations ensures that businesses operate within legal and safety boundaries, reducing liability risks and promoting operational consistency.

For example, compliance with Control Period 7 (CP7) standards is essential in the rail industry. These standards define electrical maintenance and safety requirements, and companies must align their practices with these regulations to ensure safe and seamless services.

Businesses should create and regularly update a compliance checklist to stay on top of regulatory changes. This proactive approach safeguards the company and builds trust among stakeholders, demonstrating a strong commitment to safety and quality.

Moreover, aligning with global standards and ensuring transparency in reporting can enhance a company’s reputation, fostering trust and loyalty among clients and partners. Regular audits and reviews of compliance measures further reinforce adherence to standards, enabling businesses to identify and rectify potential gaps. By adopting a culture of accountability, organisations can encourage employees to take ownership of compliance within their roles.

By concentrating on regular inspections, leveraging advanced technology, prioritising workforce training, and adhering to stringent standards, businesses can achieve sustainable electrical integrity management. Such practices ensure safety and reliability and contribute significantly to modern enterprises’ long-term success and operational efficiency.